We're all over Polished Concrete

Solutions for new and old concrete floors -

We offer a of Concrete Grinding, Sealing and Polishing systems to match your requirements

Showrooms, Retails stores, Supermarkets, Event centres, Homes, Garages, Warehouses, Patios ...

Commercial | Industrial | Residential

Repair | Prepare | Refinish. Concrete floors and surfaces

Grinding and Polishing for everyone

For over 25 years we have been Grinding and Polishing concrete across New Zealand.

We moved with the advancements in machinery, tooling and chemistry and seen real maturity in the art of concrete floor polishing.

We're proud to be on the front line of fine finishes, and offer a range of services that meet clients needs and budgets.

3 Main Systems for "polished concrete".

It's best to understand the 2 main ways to finish a concrete floor.

1) a Grind and Seal uses diamonds to abrade the surface and prepare it for a clear coating. Then a choice is made for the topical coating. This is a form of resin that creates a barrier on the surface of the concrete. Different coatings can offer different levels of gloss, chemical resistance, heat resistance and can incorporate slip reduction additives.

2) A mechanically polished concrete uses an integral sealer (densifier), that works by chemical reaction within the surface of the concrete. Finishes are then created with very fine diamonds in a refinement process until the desired gloss level is achieved.

1- Grind and Seal

There are many situations where a Grind & Seal is the best option.

A grind and seal finish is typically cheaper and faster to achieve - but that can vary depending on the quality and performance of the sealer.

A Grind&Seal can offer better performance in protection from chemical and stain attack. It can also offer greater slip resistance in wet environments.

2- Diamond Polished Concrete

Diamond polished concrete, is sometimes referred to as "mechanically polished concrete", because the finish is created by lots of machine work. For a full gloss finish a floor may be ground and polished with as many as 13 different grades of diamond tools. The concrete is enhanced by using grouting products, chemical hardeners and protective infusing sealers.

Diamond polished concrete offer superior abrasion resistance than a coating as there is nothing to scratch or wear off.

3- Hybrid Systems

A hybrid system uses more mechanical polishing than a grind and seal, to get a more refined surface, and then a thin coating system to get the desire gloss level and offer some stain and chemical resistance.

Choices to make about the floor you want!

What is the concrete you have (or will have) Like? How hard is it, how flat is it, what aggregate is in it?

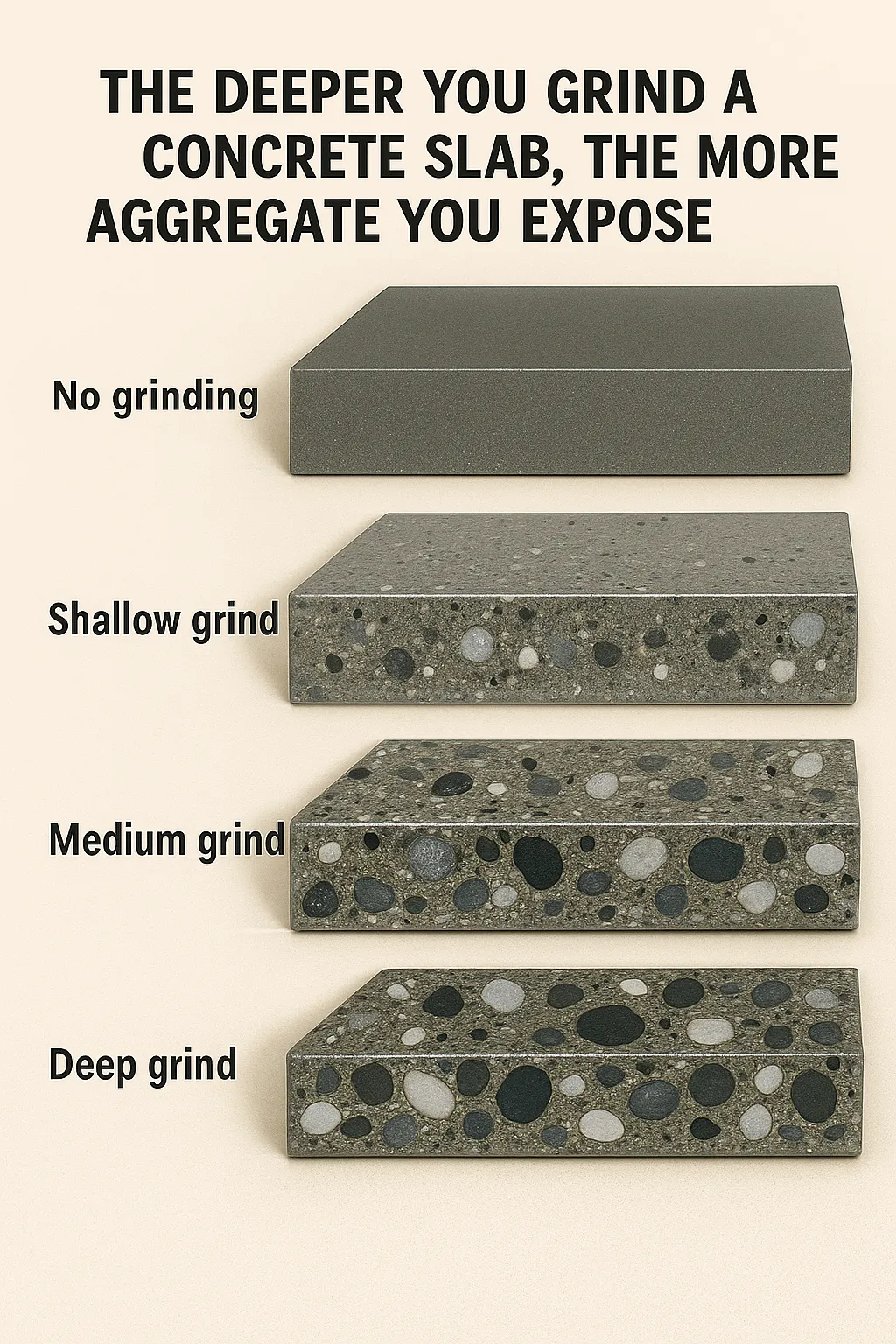

How much aggregate do you want to see? Typically the deeper we grind, the more and the larger the aggregate profile that is exposed. Choices can be a Cream Polish - we just polish the surface without grinding, virtually no aggregate exposure. Salt and Pepper - Very light grind, just start to see the tips of the aggregate. Medium Grind - moderate amount and size aggregate exposure. Heavy Grind - large and plenty of aggregate exposure. *results can vary depending on aggregate used and how it was laid and finished. The deeper the grind, the higher the price.

What finish do you want? Grind&Seal, Diamond Polish or Hybrid?

Gloss Level - this is determined by the sealer used, or the final polishing grade. The higher the gloss, the higher the price.

Tell us about your project

We rekon you're here because you are considering Grinding and Sealing or Polished Concrete for a project you have in mind.

If you're wondering how much it'll cost or have any questions, just fill out our quote request form or give us a call.

Introducing DPC 3.0

Diamond Polished Concrete Re-imagined

Polishing concrete isn’t new to us—We've been perfecting the craft since 1999. Over that time the industry has evolved through three major breakthroughs, each one lifting both the speed and quality of the finish:

Planetary grinders

– Gave us the power to cut floors flatter and smoother than ever before.

Remote control machines brought even greater repeatability and less physical strain.

Next-generation diamond tooling

– Sharper, longer-lasting diamonds and better composition sped up the grind and delivered a cleaner, crisper surface.

Concrete conditioning science

– Addressed the wild card: concrete itself. Every slab is mixed, placed, and finished under different conditions, so hidden voids, excess water, and pinholes can undermine the gloss and durability.

Even with the latest machines and diamonds, many slabs still fell short of a true showroom-level polish. To bridge that gap, we added two game-changers to our process—techniques most contractors either skip or only do halfway.

We've overcome these challenges with -

1. Mechanical Grouting

Tiny air pockets (pinholes) form naturally inside concrete. Standard polishing cuts the tops off these bubbles, leaving holes that scatter light and collect grime. Our solution is to grout the slab mechanically—often twice—forcing a fine cementitious slurry deep into every pore. The surface becomes glass-smooth and far less prone to staining.

2. Deep-Flood Densification

Conventional densifying lightly hardens the surface, but it doesn’t fill all the microscopic tunnels left behind when mix-water escapes. We “over-densify”—flooding the floor with up to three times the amount most crews use, then repeating the application one or two more times if required. Those channels fill in, locking out moisture and contaminants while raising the DOI (Definition of Image) to a mirror-like clarity (depending on the final polishing grit). Put simply: you can’t polish a hole; we make sure the holes aren’t there.

The Result

Higher gloss and clearer reflection

Stronger, more abrasion-resistant surface

Better resistance to oil, chemicals, and moisture ingress

Consistent premium finish—even on slabs once considered “unpolishable”

When the concrete beneath is properly conditioned, every subsequent polishing pass counts. That’s why Floor Masters’ advanced system delivers a floor that doesn’t just look spectacular on day one—it keeps that brilliance for years to come.

Office: East Tamai, Auckland

Call 0800 733 566

Site: www.flooringauckland.co.nz